Japan

Wood Products Prices

Dollar Exchange Rates of 10th

February 2016

Japan Yen 113

Reports From Japan

Slight year on year improvement in confidence

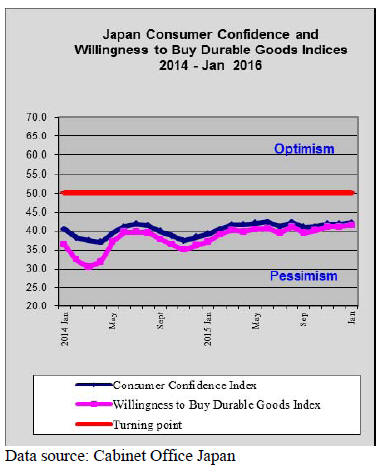

Data from Japan’s Cabinet Office is showing that the

consumer confidence index improved slightly in January.

The overall index rose to 42.1 while the willingness to buy

durable goods also rose very slightly.

Compared to a year earlier the January 2016 data reflects a

slightly more positive mood on the part of consumers

however, all the indices are well below 50 which is the

dividing line between positive and negative sentiment.

The Japanese government has kept its assessment of

the

economy at “recovering moderately” and this was borne

out by an improvement in the job market.

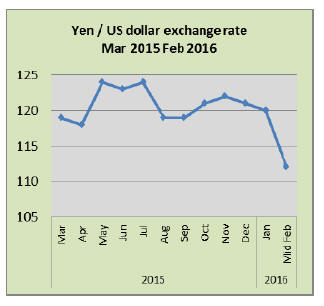

It is unlikely the positive mood will prevail however as the

yen strengthened sharply in the first weeks of February

threatening the profitability of exporters. A massive wave

of yen buying forced up the yen from around 120 to the

US dollar to 112 to the dollar at one point during the

second week of February.

Fears on the direction of the global economy exacerbated

by slowing growth in China and plummeting oil prices

have driven money to the yen as a safe haven.

Japan’s furniture import trends

Production and sales have been shrinking in Japan’s

domestic wooden furniture manufacturing sector for more

than a decade. Most of the decline is due to competition

from imports and the inability of local manufacturers to

upgrade their processing methods and raise productivity.

Wooden furniture imports continue to gain market share; it

has been estimated that imports of bedroom, kitchen and

dining-room furniture accounted for around 60% of the

market in 2015. The growth in imports from China and

Southeast Asian countries continues to hollow out

domestic wooden furniture manufacturing.

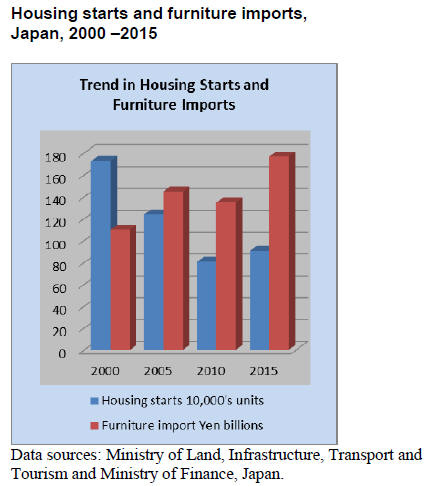

The figure below shows trends in housing starts and

imports of wooden office, kitchen and bedroom furniture.

At first sight there appears to be a contradictory inverse

relationship between trends in housing (falling) and

imports (rising). Rather than a statistical anomaly,

however, this reflects the rapid growth in the market share

captured by imports.

The Japanese furniture market was worth around yen

900

billion in 2005, and imports of wooden office, kitchen and

bedroom furniture accounted for about 16% of all

domestic sales. By 2015, the size of the market had fallen

to around yen 700 billion, and imports accounted for over

25% of the market.

Data from Japan’s Ministry of Internal Affairs and

Communications show that purchases of wooden chests of

drawers, a main item in the traditional “bridal furniture

set”, have dropped dramatically over the past 15 years. On

the other hand, household spending on dining-room

furniture has been fairly stable—although relatively small

compared with spending on bedroom items.

In the past, the bridal market was a main driver of growth

in Japan’s furniture sector. It was usual for the bride’s

family to buy a three-piece furniture set consisting of a

wardrobe, a Japanese-style chest of drawers, and a

dressing table.

Today, the traditional dressing-table has been replaced by

western-style chests of drawers and, because many newly

built houses and apartment have built-in closets, demand

for free-standing wardrobes has faded. This, combined

with the decline in the number of marriages, has upended

the established demand patterns for wooden furniture in

Japan.

Bedroom furniture

China’s exports of bedroom furniture to Japan accounted

for 57% (by value) of all wooden bedroom furniture

imports in 2015. The second-ranked supplier last year was

Viet Nam, with 28% of all imports, and other Southeast

Asian countries made up around 8%. The combined

market share of these three suppliers in 2015 was over

90%, the balance coming mainly from Europe and North

America.

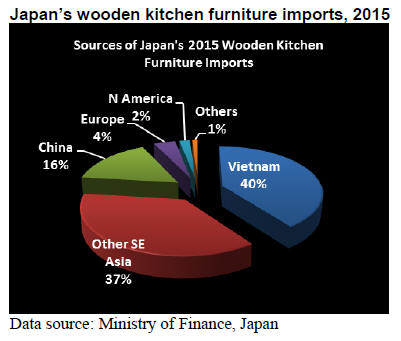

Kitchen furniture

Fitted kitchens are now a standard feature of newly

constructed houses and apartments, and the replacement

kitchen market is growing strongly as owners of existing

homes embrace renovation to avoid the cost of demolition

and rebuilding (once a feature of the Japanese housing

sector).

In the early days of kitchen modernization, European and

North American makers of kitchen units and cabinets

found a ready market in Japan. It took suppliers in Asia

only a short time to grasp the opportunity, however, and

they began growing their market share.

Manufacturers of kitchen furniture in Viet Nam have

secured a significant part of the market (41% in 2015), as

have shippers in Indonesia, Malaysia and Thailand.

Demand for European kitchen furniture tends to focus on

German and Italian lines in the up-market housing sector.

Hollowing out the furniture manufacturing base

Japan’s domestic furniture manufacturing sector has

declined as Japanese companies—even small and

medium-sized companies—have shifted production

outside Japan to countries where production costs are

lower, populations are growing and there is good

infrastructure and communications. In Japan’s wooden

furniture market, relocated Japanese companies are

responsible for much of the export trade from China and

Southeast Asia to Japan.

China was once the preferred destination for relocating

Japanese companies—it is close to Japan and has good

shipping connections. Moreover, wages and energy costs

have been much lower than in Japan, and domestic

demand has grown rapidly. This has now changed,

however: rising wages, labour disputes, and the reemergence

of bitter historical issues are causing many

Japanese companies to look elsewhere for their

investments.

Viet Nam has attracted Japanese companies, and the trade

relationship between the two countries is very close. Viet

Nam’s overall exports to Japan are now almost 10% of all

its exports, ranking second after North America. The main

products exported to Japan are garments, seafood, wood

products and electronics. In 2015, around 1000 Japanese

companies had production capacity in Viet Nam.

Expansion of single person homes creates

opportunities

Trends in Japan’s housing sector are central to the future

of the furniture manufacturing sector (whether domestic or

off-shore). Japan’s population is aging and shrinking due

to a low birth rate. The population peaked in 2005; the

number of households is increasing for now but is

projected to decline after 2019. The number of people

aged over 65 years is expected to level off in 2025 and

decline from 2040.

Superimposed on these trends is the expectation that the

population of greater Tokyo, which is rising, will begin to

fall in about ten years, when the number of households

will also begin to fall.

The other major force to influence furniture demand is the

current upward trend in one-person households, driven by

changes in culture and lifestyles, which should peak in

2030. Young professionals are shying away from early

marriage in order to focus on their careers. Since 1973

there has been a 33% decline in the number of people

getting married; moreover, the divorce rate is rising fast.

As the numbers of divorcees and never-married adults

increase, single-person households are the fastest-growing

household group and will eventually become the largest

such group in Japan. Singles need less space and can

therefore save on rent and house-building costs.

When space is limited, furniture needs to be both pleasing

and practical. Storage cabinets are popular among singles

in small homes, and many guides to living in small

spaces—with a focus on storage techniques—are

available.

Demolish and rebuild or renovate

Typically in Japan, detached wood-frame homes around

30 years old are considered worthless by lenders and by

those looking to buy. This rapid depreciation is more a

reflection of tradition than the soundness of residences,

however—homeowners in Japan were raised to believe

that wood-frame homes do not last and must be

demolished and replaced.

Understanding the extravagant waste of resources such a

tradition has created, the Japanese government has

introduced measures to encourage lenders to place a value

on renovated homes and apartments and extend the

depreciation of homes to around 50 years. The house and

apartment renovation market is booming as small,

medium-sized and even major developers are realizing its

potential.

Room for innovation and creativity

There is potential for segments of the Japanese furniture

market to grow, especially for competitively priced items

designed for singles in small spaces, such as drawers,

cabinets, fold-away dining tables and dining chairs.

Manufacturers offering a range of styles—from traditional

Japanese to Scandinavian—will find an ideal market base

if the focus is on the tasteful use of colour and simple

designs at reasonable prices.

Japanese consumers have always been rather predictable

and generally looked on low-priced goods with disdain,

preferring to shop in recognized national-brand stores and

outlets and prepared to pay for quality.

Now, however, they have started behaving like their

overseas counterparts, who for years have enjoyed

discount stores (including, in recent years, online stores)

finding low priced, serviceable items that will last until

individual tastes or fashion dictate replacement.

This fundamental shift in the attitudes and behaviour of

Japanese consumers has been reinforced by the current

state of the national economy and the impact this is having

on incomes and job security. It is likely to continue, even

when the country’s economic prospects eventually

improve.

Trade news from the Japan Lumber Reports (JLR)

For the JLR report please see:

http://www.nmokuzai.

com/modules/general/index.php?id=7

North American log and lumber import in 2015

According to tallying organizations’ rough estimated

record, log import from the North America in 2015 was

2,444,000 cbms, 19.8% less than 2014. This is sizable

drop compared to the lumber import.

Based on the Japan Lumber Importers Association’s

records lumber imports from the North America for the

first eleven months was 2,089,000 cbms, only 1.4% less

than 2014. The largest reason of decreased log import is

drop of Douglas fir log demand by plywood mills in 2015.

Plywood mills had production curtailment program last

year so that log demand declined considerably.

Actually, log import from Canada in 2015 dropped more

than 30%. Canadian Douglas fir logs are mainly used by

plywood mills in Japan. Market of Canadian Douglas fir

logs for lumber manufacturing has been steady as the

supply got tight since late last year so the prices remain

firm. Inquiries from plywood mills continue dull and slow.

This is two straight years to show decline of log import

from North America.

Increasing import of fuel for biomass generation

After Japan’s FIT system (fixed price purchase system for

renewable energy) started in 2012, many wood biomass

power generation plants started and import of fuel is

rapidly climbing.

Wood pellet and PKS (palm kernel shell) are two main

items then import of wood chip unsuitable for paper

making is expected to increase largely from now on.

Import of wood pellet for the first eleven months of 2015

was 180,863 ton, 104.1% more than the same period of

2014. By source, 113,874 ton from Canada, 37.4% more

than 2014 and 47,055 ton from China.

At present, the main users of imported wood chip is major

electric power companies, which use wooden fuel with

coal burning to reduce emission of CO2. Domestic

production of wood pellet in 2014 was 126,035 ton, 14.5%

more than 2013.

Plywood

Shipment of domestic softwood plywood continues busy.

Increasing shipment for precutting plants has continued

since last fall and the direst supply from the manufacturers

got tight in last December and precutting plants looked for

plywood in wholesale channels so the wholesalers are now

anxious to secure the volume.

Actually precutting plants made trade of necessary items

among them in December. Delivery period from the

manufacturers to precutting plants was uncertain last year

but now orders placed in early this month are promised to

be delivered by the end of this month.

Operations of precutting plants will was busy until end of

January but they seem to slow down compared to real

busy December so plywood demand will not be as busy as

before then.

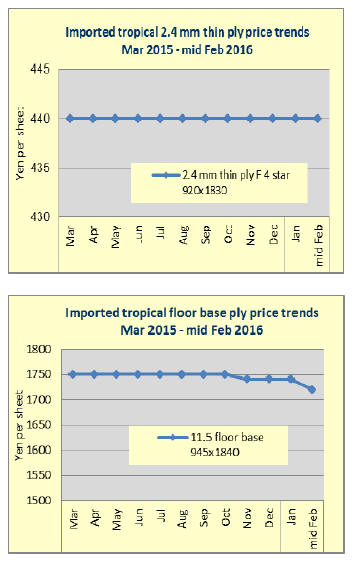

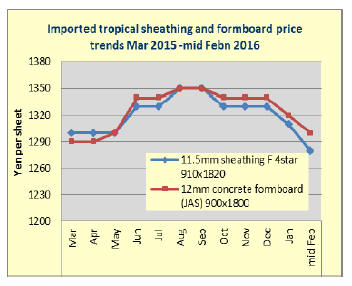

Import plywood market continues bearish. The movement

of imported plywood has been slow since last August then

the importers and wholesalers reduced the prices to move

the inventories in December but the demand for imported

plywood is considerably reduced so the users are in no

hurry to procure. They would rather wait until discount

sale comes and purchase is very limited to immediate

needs only.

Therefore, if the prices are lowered, the inventories can be

moved. The importers are anxious to move the inventories

before book closing in March but decision is hard since

discount sale means to lose money. The prices have

steadily been dropping little by little.

Sumitomo Forestry bought out American house

builder

Sumitomo Forestry Co., Ltd. (Tokyo) announced that it

bought 60% of share of DRB Enterprises, which owns

Dan Ryan Builders (DRB) group in Maryland. DRB is a

major house builder on the East Coast and South of the

United States. Purchase amount is about 10 billion yen.

New housing starts in Japan will continue declining by

dropping birth rate and aging of the population so

Sumitomo Forestry has been developing housing business

in foreign countries and by capital participation to the

DRB, it intends to be one of top builders in the States.

DRB is middle class builder to sell units built for sale in

six states of Maryland, Pennsylvania, Virginia and others

with annual sales of 1,248 units or 295 million dollars in

2014 and is ranked as 35th in the States. Employees are

299.

Sumitomo Forestry has been developing housing business

through Henry U.S.A. group, Gehan Homes group and

Bloomfield Homes group mainly in the West and the

South of the States. Now with DRB is under wing, the

East and the South are covered. Sumitomo Forestry plans

to have about 5,000 units of house sales in the States then

with house sales in Australia, total overseas houses would

be about 8,000 units.

Nihon Flush expands sales in China

Nihon Flush Co., Ltd. (Tokushima prefecture) plans to

increase sales to marketing agents of building materials in

China.It has 30 marketing agents in China and it plans to

expand sales with its brand ‘Nichimon’.

The company manufactures and markets systemized

building materials like interior doors and have been

supplying materials to large developers like China Vanke

Co., Ltd.Present sales amount in China is about eight

billion yen, which is about 60% of the company’s total

sales amount.

Supply to large developer like Vanke gives reliability of

the products and there are more requests from other

companies to have business with Nihon Flush so the

company decided to expand the more sales in China. In

two to three years, the sales amount in China would be as

big as 10 billion yen.

|